Cooling technology + supply

Description of cooling technologies under consideration of different re-cooling options, district cooling networks and combined cooling as well as heat and power production

The high cooling demand in industrial processes and the increased demand of cooling for the air conditioning of office- and commercial buildings due to modern architecture (glass fronts) as well as the climatic increase of the ambient temperatures in Europe lead to the increased installation of local cooling plants. Thus, a higher electric power demand is necessary during the summer season. Therefore, the development of innovative and energy efficient concepts for cooling under consideration of the particular site constraints are required.

The centralised supply of several consumers with cooling energy and the application of combined cooling, heat and power production plants with absorption chillers are promising alternatives. These concepts allow the reduction of the electric power demand and the utilisation of renewable energy based on biomass or waste heat for cooling.

The installation of centralised cooling plants is an economically and ecologically feasible option in urban areas with potential cooling consumers (office, commercial and public buildings, hospitals, train stations etc.) compared to decentralised chillers (e.g. split coolers). The integration of absorption chillers and free-cooling applications during the winter season are special advantages of centralised cooling plants.

Basic design of centralised cooling plants

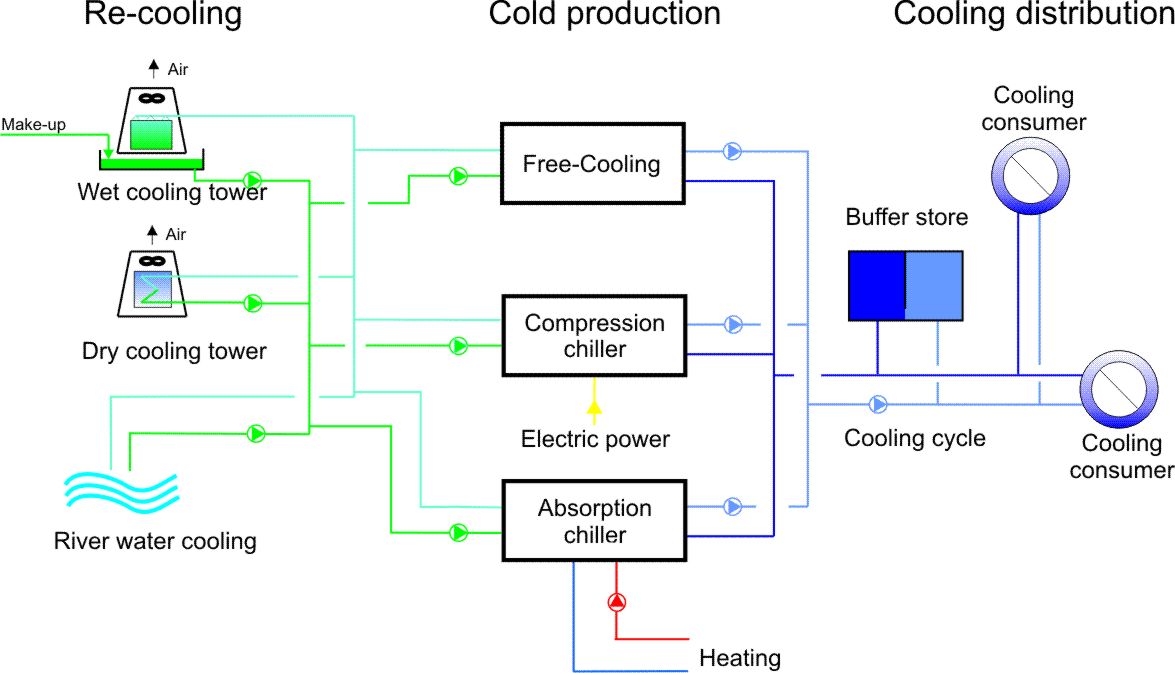

Figure 1 shows the possible layout of a cooling plant based on absorption and compression chillers and different re-cooling technologies.

Figure 1: Possible layout of a cooling plant

The main components of cooling plants are the chillers, the re-cooling plant and the distribution of the cooling energy:

- Cooling: The production of cooling energy is based on three different energy sources.

- Electric power: A compressor (piston, screw or turbo compressor) driven by electric energy compresses the refrigerant (e.g. ammonia, R134a, CO2) which then condenses due to the re-cooling of the refrigerant. Thereafter, the refrigerant is expanded in an expansion valve causing a temperature drop and thus allowing the cooling of the secondary cooling cycle (e.g. water, ammonia or glycol). Thereby the refrigerant is evaporated and fed into the compressor.

- Heat: Absorption chillers utilise heat in form of hot water or steam in a thermodynamic cycle for the cold production. Possible heat sources are district heating plants based on fossil or renewable fuel, waste heat or solar heat. The thermodynamic cycle of absorption chillers is based on a refrigerant and a solvent. The refrigerant must be totally soluble in the solvent. Absorption chillers based on lithium bromide and water achieve cold water temperatures of 3°C while the minimum temperature of the heat source needs to be 80°C. In order to achieve lower temperatures with absorption chillers the application of ammonia as refrigerant and water as solvent and higher temperatures of the heat source are required. Other technologies such as adsorption chillers or diffusion chillers are also suitable for cooling based on heat.

- Free-Cooling: A heat exchanger connects the cooling cycle with the re-cooling cycle and allows a direct cooling of the cooling cycle by the re-cooling unit. Therefore, no chillers and no additional energy for the cold production are necessary. Free-cooling applications are depending on the re-cooling technology applied and the climatic conditions and are mainly applicable during the winter season.

- Re-cooling: The thermal energy which is transferred from the cooling cycle to the chiller and the electric or thermal energy input needs to be re-cooled. Generally, the following cooling systems are available:

- River water cooling

- Dry cooling towers

- Wet cooling towers

- Hybrid cooling towers

The selection of the re-cooling technology depends on site constraints such as the climate, the availability of cooling water and the required space. The re-cooling demand of adsorption and absorption chillers is significantly higher than the one of compression chillers and has to be considered appropriately.

- Distribution of cooling energy: The achievable temperature difference between feed and return flow of a district cooling system is considerably lower compared to the one of district heating systems. The air conditioning of buildings, which is the most relevant cooling application, requires feed temperatures of approximately 6 to 12°C. Hence, the flow rate in district cooling systems increases and larger pipe diameters are required compared to district heating networks. Furthermore, the investment costs and the operation related costs increase due to pipe size and increased pumping. The trend of the daily cooling demand of a district cooling system typically shows rather high short-term peak loads. The integration of storage tanks is a feasible option in order to provide the cooling energy needed during such peak loads. This way, the cooling capacity of the compression chillers installed can be reduced and the cooling energy provided by absorption chillers can be increased.

The type and design of the cooling technology strongly depends on the particular site constraints and needs therefore to be adjusted accordingly.

The most relevant parameters influencing the design of a centralised cooling plant are:

- Type of consumers connected to the district cooling system: The type of consumers (air conditioning or process cooling applications), the cooling demand and the internal cooling system of each consumer determine the required cooling capacity and the feed temperature of the cooling cycle.

- Cooling demand trend: The time dependent load rate (daily, weekly, monthly and annual profile) influences the number of chillers installed and the cooling capacity of each chiller. The cooling demand trend needs to be especially considered for the integration of free-cooling applications since free-cooling is only applicable during the winter season.

- Available energy sources: Heat sources such as a connection to a district heating system or waste heat allow the integration of absorption/adsorption chillers into the overall plant concept.

- Plant site and required space: The plant site defines the available re-cooling options. If there is no possibility to utilise river water for re-cooling, enough space for the installation of cooling towers has to be considered. Generally, the distance to the cooling consumers should be as short as possible.

The basis for an optimised design of cooling plants is a detailed evaluation of potential heat consumers. Only a comparison of different plant options considering the cold production, the re-cooling as well as the cooling energy distribution with a reference scenario and a detailed cost calculation as well as the determination of the cold production costs based on the plant options evaluated lead to a technically and economically feasible cooling plant.

Combined cooling, heat and power production

The combined cooling, heat and power production (trigeneration) is an enhancement of existing CHP technologies. The utilisation of heat from CHP plants in absorption chillers increases the utilisation rate of the CHP plant (e.g. based on the steam process or the ORC process) and the electric power output respectively. Moreover, the application of absorption chillers reduces the electric power demand of the cold production.

Trigeneration plants are especially suitable for district cooling systems and process cooling applications. The utilisation of heat based on biomass CHP plants or waste heat allows the production of cooling energy based on renewable and CO2 neutral resources.

Trigeneration plants are rather complex since the systems for the cooling, heating and power production need to be combined and adjusted. The basis for an optimised design is a detailed evaluation of the heating and cooling demand and their daily, weekly and annual trends as well as the temperatures needed for each process.