Biomass Pyrolysis

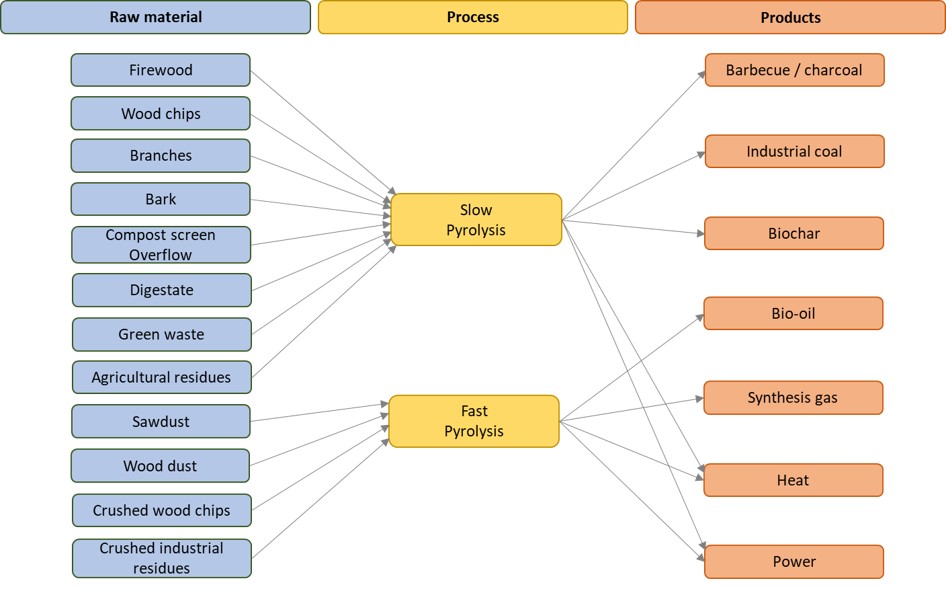

The processes described in this section focus on the production of charcoal or bio-oil (main products) besides heat and power. Bio-oil can be further refined to liquid transportation fuels or can be directly used as storable fuel in turbines or bio-oil burners. Biochar can be used as barbecue coal, industrial coal (substitute for fossil coal), soil amendment and fertilising agent, an additive for animal feed or in the pharmaceutical industry.

Biochar production from beech wood (left) and from maize cobs (right)

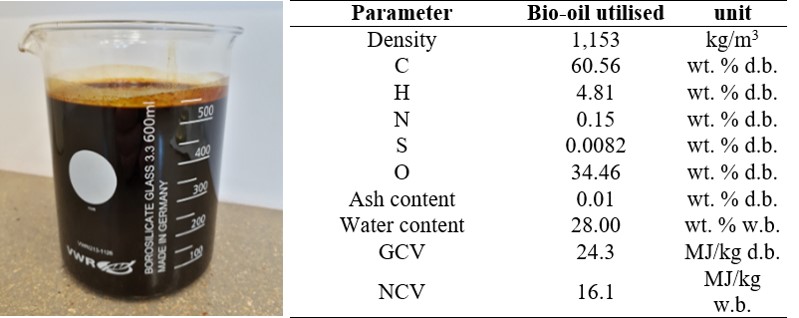

Bio-oil from the pyrolysis of softwood and its chemical composition / properties

For biochar production also biological low-grade residues such as screen overflow from composting plants, digestate from biogas plants or green waste can be used, which cannot or only with difficulties be used in conventional processes for energetic biomass utilisation due to their high ash contents.

Bio-oil and pyrolysis gas can be further refined to high-grade liquid biofuels or can be used on site or external of the production process for the generation of heat and power.

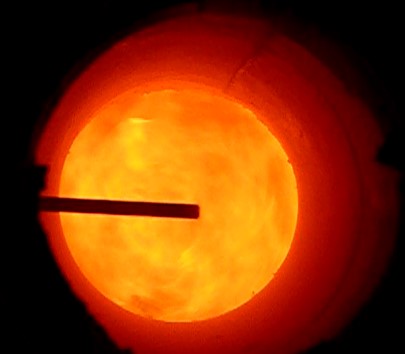

Outlet of a turbine combustion chamber fired with bio-oil (Source: OPRA Turbines International BV).

View into an ultra-low-emission pyrolysis gas burner developed by BIOS.

Following, by such biorefineries based on biomass pyrolysis a valuable raw material can be produced besides green heat and power, which results in an additional benfit.

Raw materials – processes – products

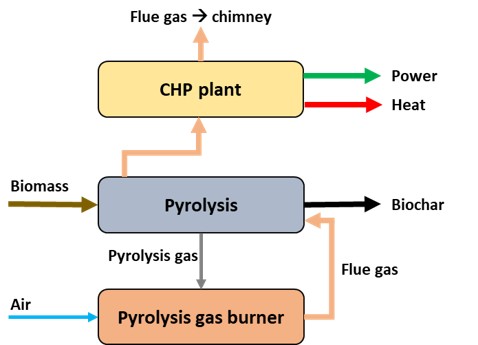

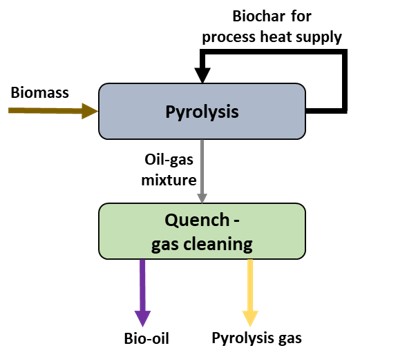

The figure below as well as the two process schemes provide an overview, from which raw materials which products can be produced by means of pyrolysis processes.

For the production of biochar slow pyrolysis technologies (in batch or continuous operation) are used. They are operated at temperatures of 400 to 500°C and residence times of typically more than an hour. The particle size of the biomass used ranges from coarse chips to wood logs with a moisture content of typically between 5 -10 wt.% (w.b.).

For the production of bio-oil fast pyrolysis technologies in continuous operation are used. They are operated at temperatures of typically 500°C and residence times of a few seconds only. The particle size of the biomass used is usually below 5 mm with a moisture content around 5 wt.% (w.b.).

Pyrolysis processes, their input materials and the possible products

Verfahrensschema 1: Langsames Pyrolyseverfahren zur Biokohleproduktion mit gekoppelter KWK-Anlage.

Verfahrensschema 2: Kontinuierliches Schnell¬Pyrolyse¬verfahren zur Produktion von Bioöl und Pyrolysegas (Pyrolysegas kann zur Wärme- und Stromproduktion eingesetzt werden).

During biochar production typically 60% of the energy content of the ingoing biomass remain in the biochar. Around 30% of the energy input can be used for heat and power generation. The overall process efficiency is around 90%.

During bio-oil production typically 65% of the energy content of the ingoing biomass remain in the bio-oil. Around 20% of the energy input can be used for heat and power generation. The overall process efficiency is around 85%.

Products

Charcoal: Due to its high quality (properties according to DIN EN 1860-2) the charcoal produced from wood can be used as barbecue coal. Moreover, its use as industrial coal is also possible, e.g. as a raw material for the production of activated carbon or in the pharmaceutical industry.

Biochar: Agriculture is the main field of application for biochar. It can be used to improve soils (increased water retention capacity, improved heavy metal binding) and as fertiliser. For the use as a fertiliser the biochar must be loaded with nutrients, which can e.g. be reached by preceding use as animal bedding (cascaded use of biochar). Composting the biochar together with other compostable materials is another possibility to enrich it with nutrients. Both possibilities are able to reduce nutrient losses, mineral fertilisers can be saved and nutrient cycles can be closed. The relevant quality parameters for this use are stated in the "European Biochar Certificate". Another possibility to use biochar is its use as additive in animal feed. In this case, the biochar and its production must be certified according to GMP+ (Good Manufacturing Practices).

Bio-oil: Modern pyrolysis technologies with subsequent catalytic reforming allow a high quality of the bio-oil produced (low acid content, good storability due to low polymerisation tendency, low viscosity), so that it can directly be used in combined heat and power plants. After treatment of the bio-oil by hydration the production of higher quality liquid fuels (replacement of liquid fossil fuels) is also possible.

Pyrolysis gas: Pyrolysis gas exhibits a high heating value and mainly consists of H2, CO, CH4, H2O, CO2, tars and hydrocarbons. It can directly be used in pyrolysis gas burners. After an appropriate cleaning step it can also be used in engines or fuel cells as well as in chemical synthesis processes such as the production of hydrogen.

Heat: The waste heat from pyrolysis processes can be used internally to dry the raw material or to supply process and district heating networks.

Power: The electricity produced can be fed into the public grid (depending on the raw material used) or used to cover the own electricity demand of the pyrolysis plant.

Economy

By the production of a valuable raw material (bio-oil or biochar) in combination with heat and power, an additional benefit can be achieved in comparison to conventional biomass heating or CHP plants.

Advantages for users

Chemical industry and utilities: Replacement of fossil energy carriers by biological raw materials such as biocoal, bio-oil and pyrolysis gas, which can be produced with high exergetic efficiency and are almost CO2 neutral.

Operators of biomass heating plants: The high-quality biochar produced from local raw materials can be marketed as a valuable product. Compared to a conventional biomass heating plant the amount of heat produced is lower, which increases the possible annual operating hours (the year-round use of the heat produced is easier).

Operators of composting plants, biogas plants and waste management centres: Upgrading of waste materials by conversion into high-quality raw materials and energy carriers as well as heat and power.

Municipalities: Utilisation of waste materials such as green waste from landscape management in an ecologically meaningful way.

Farmers: The use of biochar as animal bedding or in composting and its subsequent use on farmland can improve soils and exhibits fertilising properties. Moreover, nutrient losses can be reduced, industrial fertilisers can be substituted and CO2 sequestration is enabled.

Procedure for the selection and evaluation of biomass pyrolysis technologies

As a basis for the decision whether a biomass pyrolysis plant is feasible, the following criteria have to be considered:

- Technological evaluation and comparison of different biomass pyrolysis systems in order to evaluate their maturity as well to select the best possible solution for the framework conditions given

- Economic evaluation of the pyrolysis technologies compared to a reference system (e.g. biomass CHP plant based on combustion or gasification)

- Evaluation of already available reference plants for a particular pyrolysis technology – important, in order to obtain information regarding reliability and availability

- Evaluation of the emissions caused by the pyrolysis technology (exhaust gas, waste water, ash) and comparison with the expected emission limits

- Overall evaluation of the systems based on the outcomes of the points mentioned above

BIOS BIOENERGIESYSTEME GmbH performs this evaluation procedure based on appropriate expertise and on a neutral basis.

Working field of the BIOS BIOENERGIESYSTEME GmbH

- Development, comparison as well as technical and economic evaluation of different biomass pyrolysis technologies as a basis for the selection of an adequate technology for the framework conditions given

- Feasibility studies and check for funding options

- Preparation of permit applications and proposals for funding

- Detailed design, request for proposals (RFP)

- Supervision of plant construction and commissioning

- Plant monitoring, process and performance optimization