BIOBIL

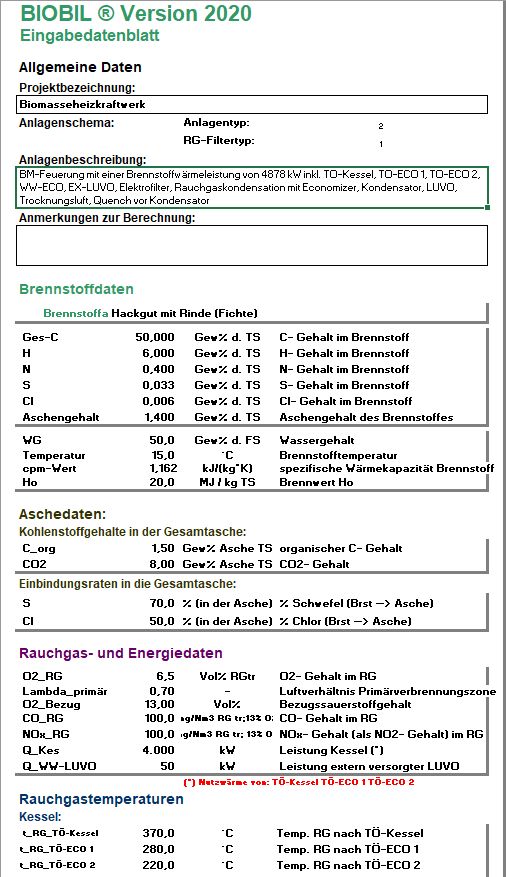

Program for the detailed calculation of the mass and energy balances of combustion plants with different fuel inputs (solid / gaseous / liquid, focus: biomass). Multi-stage boilers (water / steam / thermal oil) and multi-stage heat recovery systems (including a condensation unit and an air preheater) are considered.

Based on MS-Excel and VBA

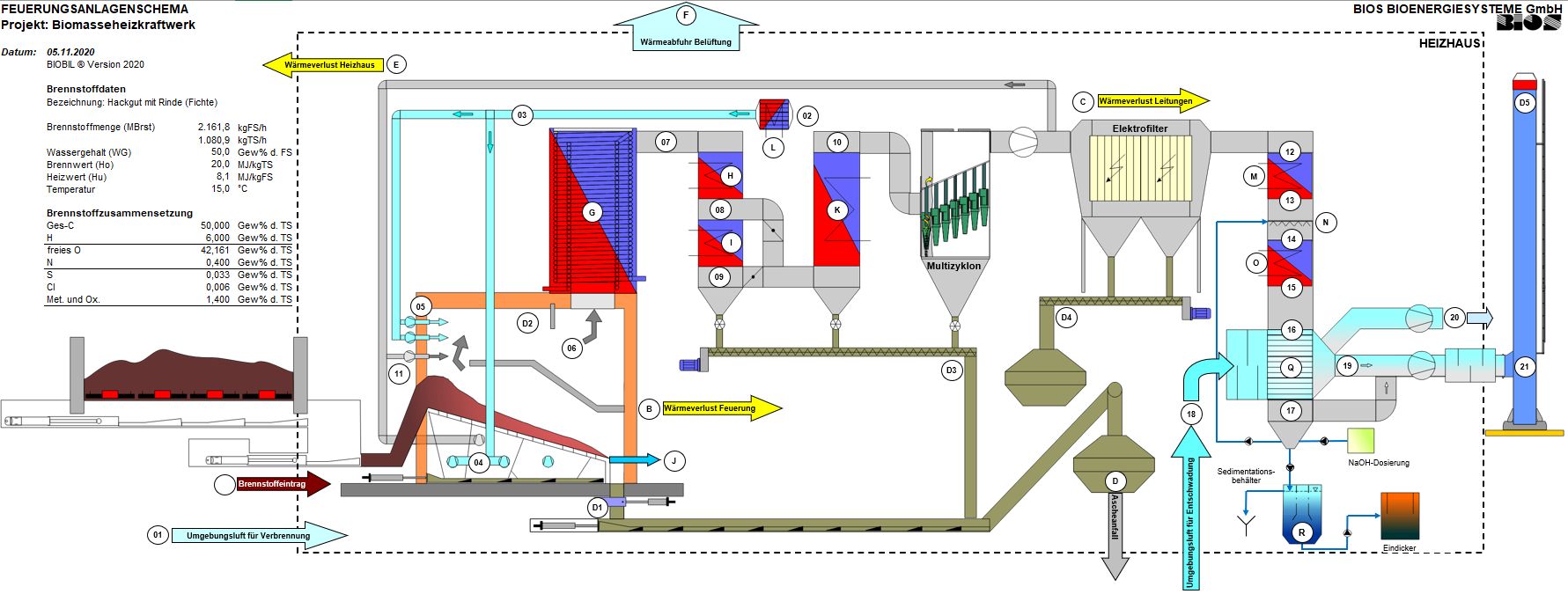

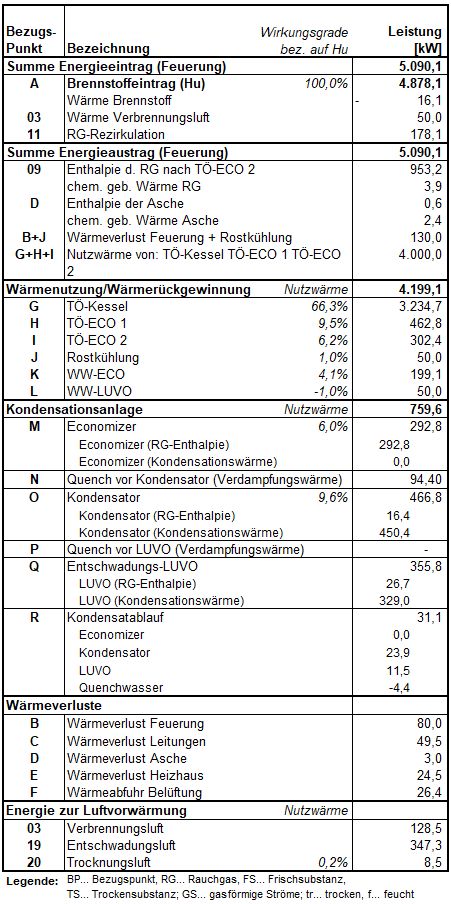

The results are presented in tables for subsequent processing and in a clearly arranged flowsheet

What is the program suitable for?

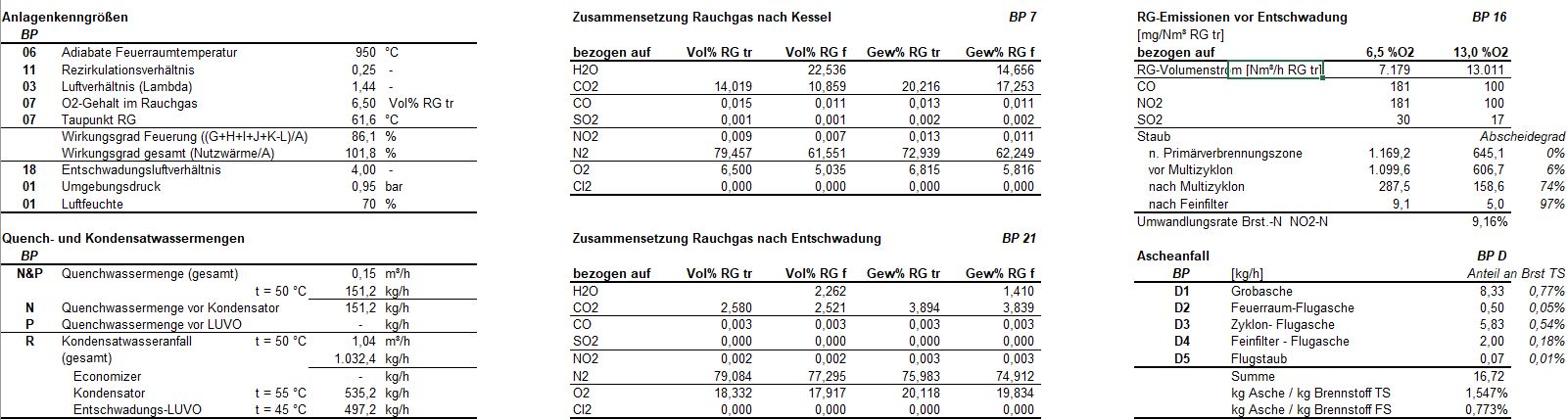

- Design of combustion plants: calculation of the gas streams (flue gas, air) in the different plant sections, of the fuel used, of the amount of ashes produced, performance of mass and energy balances, efficiency calculations

- Evaluation of the performance of combustion plants based on operating data: calculation of the average heat produced and the average efficiencies (over a given evaluation period), plausibility check of the operating data and the amounts of ashes and condensate produced

What is calculated?

- Composition of the fuel (dry base and wet base)

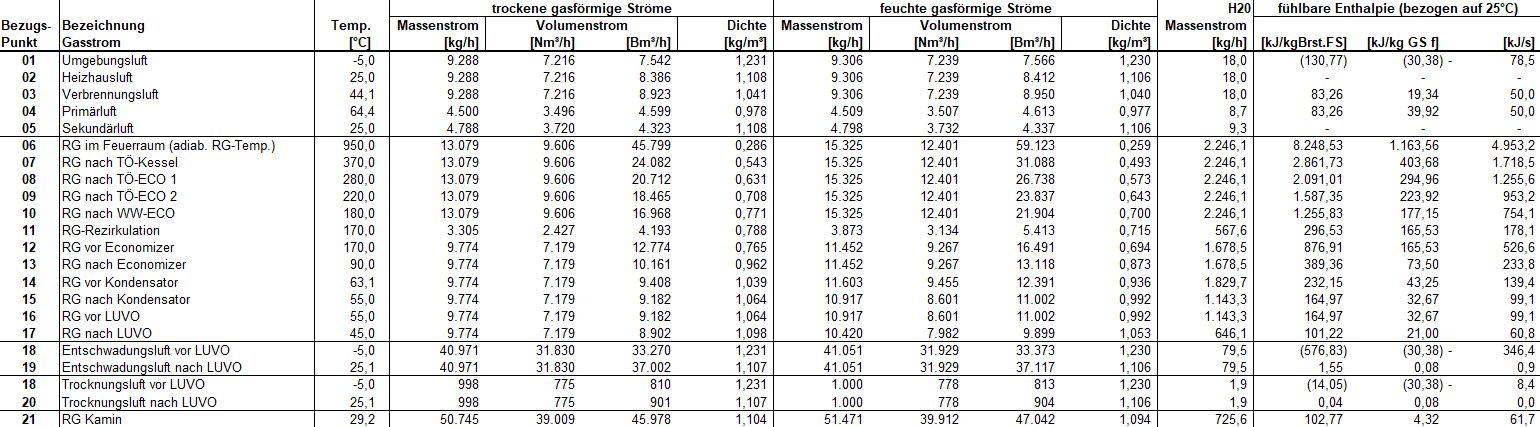

- Combustion air used (in mol/kg fuel (w.b.), kg/kg fuel (w.b.), Nm3/kg fuel (w.b.), m3/kg fuel (w.b.), mol/h, kg/h, Nm3/h und m3/h)

- Composition of the flue gas in the different plant units

- Amount of the flue gas in the different plant units (in mol/kg fuel (w.b.), kg/kg fuel (w.b.), Nm3/kg fuel (w.b.), m3/kg fuel (w.b.), mol/h, kg/h, Nm3/h und m3/h)

- Density of the flue gas at different temperatures

- Amount of condensate produced

- Contents of dust in the flue gas

- Amount of ashes produced

- Visualisation of all relevant energy fluxes of the plant

- Specific performance parameters (adiabatic flue gas temperature, dew point of the flue gas, direct and indirect efficiencies with and without heat recovery unit)

- Presentation in a clearly arranged flowsheet

Download: